Grayloc® Clamp Connectors

Field-proven, compact, and lightweight alternative to conventional flanges.

Our trusted Clamp Connector design provides a simple-to-install solution that saves both space and weight across your operations. Delivering unparalleled design quality and reliability since the 1950s, our connectors feature metal-to-metal bore seal technology to meet your critical service piping and vessel connection requirements. The connectors’ light weight, smaller diameter, and shorter length support the design of optimized systems.

Reduce installation time with quick and easy assembly

Eliminate fugitive emissions

Reduce maintenance costs and spare parts inventory

Grayloc® Clamp Connector Videos

How Does a Grayloc® Clamp Connector Work?

Learn how the Grayloc® Clamp Connector creates a reliable, metal-to-metal seal. See why it’s a trusted solution for high-pressure, high-performance environments.

Why are Grayloc Clamp Connectors Better than Flanges?

Discover the key performance advantages of Grayloc® Clamp Connectors over traditional flanges—including improved sealing integrity, lighter weight, and reduced installation time.

Grayloc® Clamp Connector Variations for Critical Applications

Explore the full range of Grayloc® Clamp Connector configurations, sizes, and materials engineered to meet diverse project needs.

Grayloc® Clamp Connector Installation and Operation

Master the steps to assemble, disassemble, maintain, and repair Grayloc® Clamp Connectors.

Technical Specifications

| Nominal pipe size | ½ to 64 in |

| Design pressure rating | From full vacuum up to 60,000 psig |

| Design temperature range | -423 to 1700°F / -253 to 927°C |

| Hub | Nickel alloys, carbon, low-alloy, stainless and duplex stainless steels |

| Seal Ring | Nickel alloys, low-alloy, stainless and duplex stainless steels |

| Bolting | Nickel alloys, low-alloy, stainless and duplex stainless steels |

| Clamp | Nickel alloys, carbon, low-alloy, stainless and duplex stainless steels |

| ASME B31.1, Power Piping |

| ASME B31.3, Process Piping |

| ASME B31.4, Pipeline Transportation Systems for Liquids and Slurries |

| ASME B31.8, Gas Transmission and Distribution Piping |

| ASME B31.12, Hydrogen Piping & Pipelines |

| ASME Section I |

| ASME Section VIII Div. 1 |

| ASME Section VIII Div. 2 |

| ASME Section VIII Div. 3 |

| API 6A: Specification for Wellhead and Christmas Tree Equipment |

Product Documents

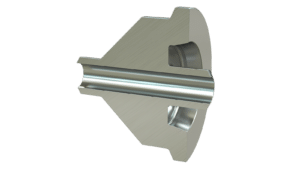

Product Variations

- Clamps

- Hubs

- Seal Ring

Typical Applications

- Maintains sealing performance while withstanding the extreme pressure, temperature, and external load requirements of the most challenging testing and operational applications

- Efficient and zero leakage connectors are ideal for the high pressures and temperatures found in biomass and renewable natural gas applications

- Used in cryogenic applications to provide sealing performance that far exceeds conventional flanges

- Clamps produced in accordance with food safety standards are available to enhance the capabilities of your food production facility

- Extensive track record of use in hydrogen service across industries

- Ensure safe, leak-free operation with difficult-to-seal services

- Meet the highly challenging conditions imposed by molten salt applications

- Superior design and sealing capabilities meet criteria for applications ranging from small scale testing to full scale power generation

- Trusted components in hardware including reactors, heat transfer systems, and cooling systems

- Easily integrated into original equipment manufacturer designs

- Extensive industry track record of zero leak performance in high pressure systems

- Easy assembly, minimal maintenance requirements, and superior performance compared to conventional flanges

- Small footprint and easy installation support steam, oil, and water applications

- Superior performance makes our connectors the preferred option in the most demanding refining applications including difficult to seal gases, extreme pressures, extreme temperatures, and thermal transients

- Fewer studs and lower assembly torque enable superior sealing and quick installation

-

Meets pressure and temperature requirements of supercritical applications including heat transfer and extraction

-

Lower weight, compact design, and quick assembly times ideal for use in pressurized tidal energy applications

-

Offer significant opportunities for reduction of CAPEX and OPEX by saving space, weight, and time compared to conventional flanges

Real Impact. Real Savings.

Read our case studies featuring Grayloc Clamp Connectors.

Contact Us

The Grayloc® Products team is ready to help you.

We offer best-in-class products, backed by unparalleled quality, reliability, and global support. Complete the form and your message will be sent directly to a Grayloc representative in your region.

Grayloc® Products operates worldwide. Explore our locations.

"*" indicates required fields